The FYXD-16028 tag is a kind of RFID electronic tag without power supply developed by UHF tag chip. The speed is collected by the acceleration sensor chip through the MCU and output through the UHF chip.

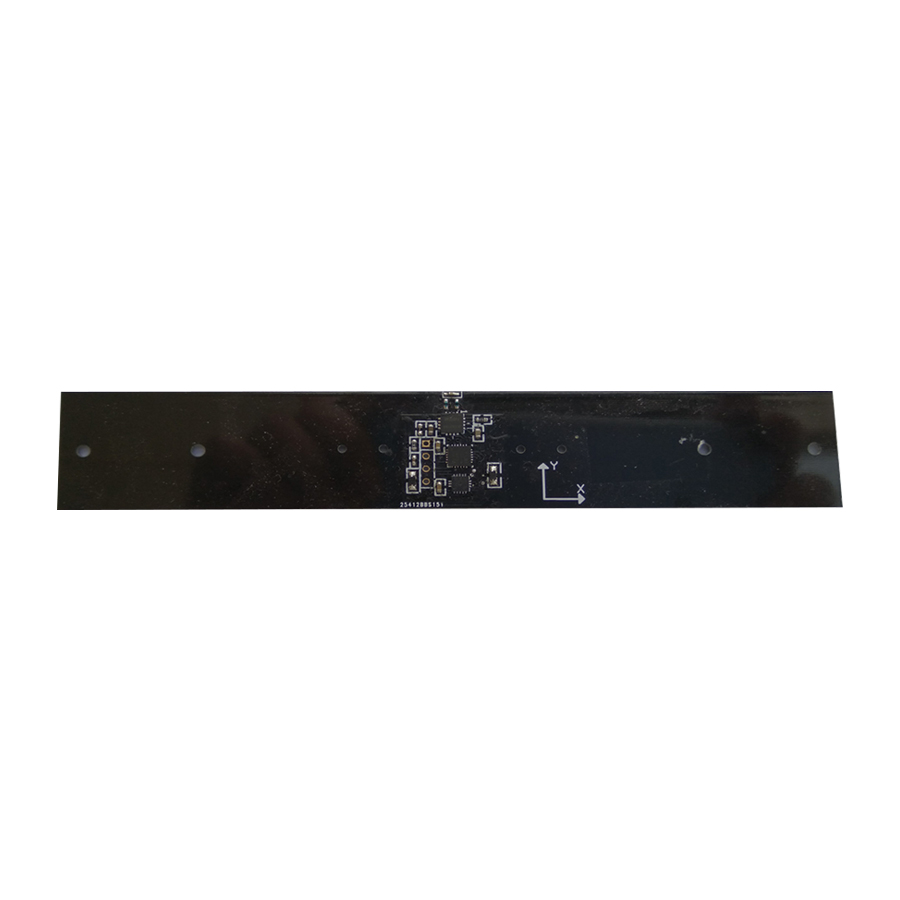

FYXD-16028 tag consists of UHF electronic tag, controller and acceleration sensor. The size of the label can be designed according to the user’s needs, and it can be equipped with a casing, which can reach the protection level of IP67~IP68. Meet the use requirements in different environments.

To read FYXD-16028 tags, EPC C1G2 reader must be used. In addition to the communication protocol of the reader, other factors should also be considered. The tag has a built-in capacitor, and it takes 1 to 5 seconds to fully charge the capacitor. In order to make the voltage full as soon as possible, the reader must continue to read the tag, so that the energy can be continuously filled through VDD to reach the working voltage of the peripheral circuit. FYXD-16028 By reading the label user area address and the corresponding parameter list

| Address | word length | Data type |

| 0x100 | 5 | int |

The scope of application of this product: rough loading and unloading of cargo transportation, geophones, detection of equipment attitude, pedometer function, inclination measurement, vibration intensity detection…etc.

Application scenario of railway sleeper label

The UHF reader is installed at the bottom of the locomotive, and the acceleration label is installed on the upper surface of the sleepers.

There is an acceleration sensor inside the label, the sensor chip is the water surface, the vertical chip is the Z axis, and the horizontal direction is the X and Y axes, and X and Y are at right angles on the horizontal plane. The sensor can detect the acceleration in the three directions of XYZ in real time, and transmit the acceleration value to the reader through the ultra-high frequency wireless chip.

The reader is installed at the bottom of the locomotive and continuously scans the tags on the track. As long as the tag is detected, it reads the tag ID and reads back the acceleration value of the sensor at the same time.

By analyzing the acceleration of the tag, you can detect the vibration of the rail, analyze the vibration data of the tag sent by the reader, analyze the vibration and vibration frequency of the sleeper, judge the intensity of the vibration of the sleeper, and alarm in time if the limit is too high to avoid vibration Excessive assembly will cause cracks, fatigue, fracture, contact surface wear and loose fasteners on the rails, prompting the rails to be scrapped in advance, and even cause tragic accidents of car crashes and deaths in severe cases.

Using sensor tags for rail vibration detection has the following advantages: