Study the application of RFID technology in the automobile assembly line

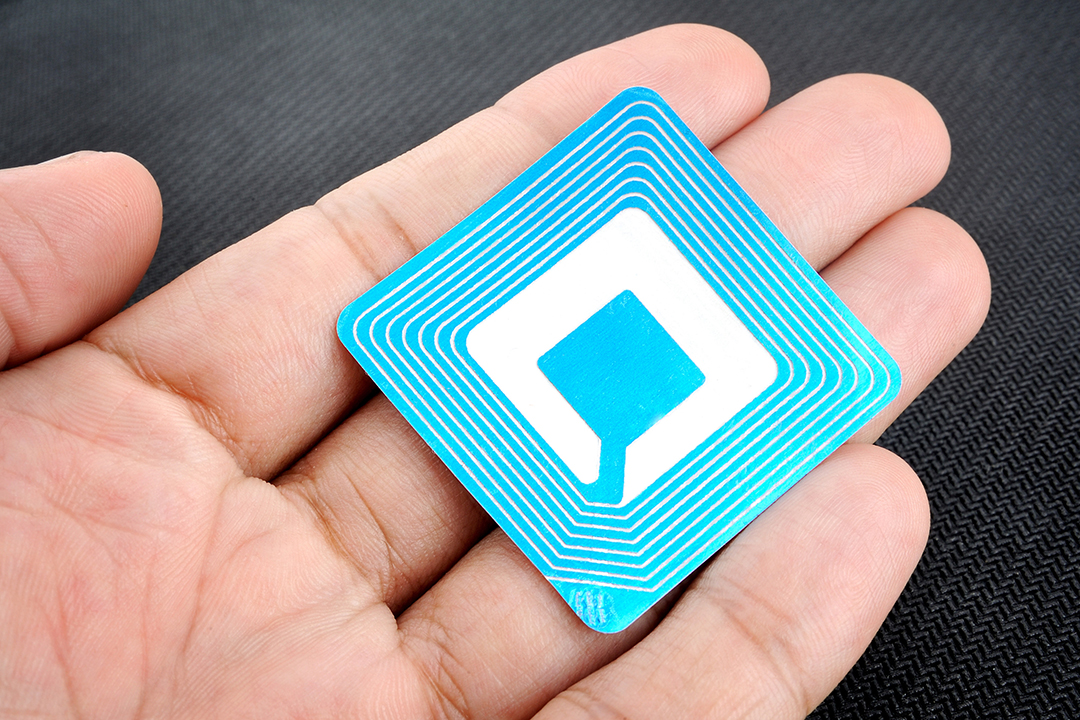

RFID (Radio Frequency Identification) is a non-contact automatic identification technology, which uses radio frequency signals to achieve non-contact information transmission through spatial coupling (alternating magnetic field or electromagnetic field) and achieves the purpose of identification through the transmitted information. The identification work does not require Manual intervention has the advantages of large data storage, readable and writable, non-contact, long recognition distance, fast recognition speed, good confidentiality, strong penetration, long life, good environmental adaptability, and the ability to identify multiple tags at the same time, and Can work in various harsh environments.

In the discrete manufacturing industry, the production workshop is the central place of product manufacturing, the starting and ending node of finished product logistics and supply logistics, and the manufacturing capacity of the workshop and its internal logistics capacity play a decisive role in the production capacity of the enterprise. The Manufacturing Execution System (MES) is the hub for undertaking the ERP (Enterprise Resource System, Enterprise Resource Planning) system, coordinating the SCM (Supply Chain Management, Supply Chain Management) system, and scheduling the underlying production control system. played an important role. Fierce market competition has put forward further requirements for modern manufacturing, which are manifested in the following aspects: a small amount of multi-variety production mode, ever-shortening production cycle, and timely response to the changing needs of customers. All of these require modern manufacturing to have a higher degree of automation and informatization. It has become a top priority to study and apply RFID technology, explore and reorganize the information flow of enterprises, maximize the existing resource advantages of my country’s manufacturing industry, and promote the technological progress of enterprises and the upgrading of traditional manufacturing industries. Integrating RFID technology into the MES system must be one of the many ways to promote the development and upgrading of traditional manufacturing industries.

1. System requirements analysis

As a typical situation in discrete industrial production, automobile assembly production activities have the following characteristics: the production process is parallel and asynchronous, the redundancy of equipment functions is large, the control quantities are independent of each other, the management of production resources is complex, and the parts in the production process are in a discrete state. State, the production and manufacture of vehicles is mainly realized through physical processing and assembly.

Based on the specific situation of an automobile manufacturer in Anhui Province, this paper studies the application mode of RFID technology on the automobile assembly line.

At present, the company mainly uses barcode technology on the automobile assembly production line. The employees at the station manually scan the VIN code of the body and the barcode of the parts to track the vehicle and collect assembly information. The entire collection process is relatively time-consuming. When the barcode is damaged or stained and cannot be recognized, employees need to manually enter the vehicle VIN code or part code, which has a high error rate and takes a long time, making it difficult to speed up the production cycle. The visibility of the production site needs to be improved. It is necessary to provide real-time and accurate assembly guidance for workers to prevent the occurrence of missed and wrong installations. The assembly status of production line vehicles also needs to be monitored in real time. The feedback of material consumption information is not timely, and it is difficult to realize the real-time pull of production materials, resulting in excessive inventory of production materials and affecting the flow of funds. The lack of associated management of employees and their assembly parts makes it difficult to assign responsibility to people when tracing quality problems caused by manual operations.

RFID technology is not just a simple replacement of barcode technology, its application in discrete manufacturing will change the way of production and operation of discrete manufacturing enterprises. Since RFID technology has many advantages mentioned above, using it instead of barcodes to identify and track vehicles on the automobile production line without manual intervention in the whole process can greatly reduce the labor intensity and error rate of workers. Nowadays, RFID technology can be used to realize automatic, high-speed and effective recording, reduce the labor intensity of operators, and thus improve the pass rate of products off the assembly line.

Applying RFID technology to the automobile manufacturing industry and integrating it into the MES system can improve the management and control level of the production process, and effectively track, manage and control the resources required for production, including materials, equipment, and human resources; combined with the upper management system , can reasonably schedule and manage these resources, improve manufacturing competitiveness, improve production organization, shorten production cycle, reduce the quantity of work in progress, improve product quality and reduce human resource consumption. It has important theoretical significance and application solutions for developing discrete manufacturing manufacturing system models and application solutions, improving the level of visual monitoring of manufacturing processes and product quality tracking, promoting the formation of RFID technology application standards in the manufacturing industry, and driving the development of my country’s RFID technology industrialization. Value.

2. System goals

Based on the above demand analysis, the following overall system goals are proposed: make full use of the technical advantages of RFID, combined with the MES system of the assembly shop, to solve the problem between the planning layer of the enterprise’s current ERP system and the process control layer of the workshop automation system, LES (Logistic Execution System, logistics) Execution system) Information and management faults between the internal logistics level of the workshop and the production control layer of the MES system, and between the vehicle quality traceability system and the original MES system, to realize the visualization and digital management of manufacturing and quality. Specifically broken down into the following sub-objectives:

(1) Combining RFID technology with the production line scheduling system to realize intelligent production line scheduling on the basis of automatic production line scheduling.

(2) Integrate RFID technology into the assembly stations of the production workshop, use RFID tags to identify parts for data collection, keep abreast of production line material consumption information, and pull supply logistics without delay to further meet the needs of the JIT supply model; Important components are recorded for installation to provide detailed and reliable data support for the quality traceability system.

(3) Combine RFID technology with on-site visualization system to provide real-time and accurate assembly guidance to workers at the station.

(4) Combining RFID technology with the workshop personnel management system and quality traceability system, in addition to realizing the function of personnel management, it can also record the assembly operation and realize the assembly responsibility to be assigned to the person.

3. Application scheme of RFID technology in automobile assembly line

The application scheme involves two different types of RFID tags, high frequency (13.56MHz) and ultrahigh frequency (915MHz), and the specifications of the selected RFID tags are shown in Table 1 and Table 2.

Among them, personnel are equipped with high-frequency RFID tags, which store employee ID and basic information; a high-frequency RFID tag is placed in each parts box, and the part number is stored in the tag; a UHF RFID is placed on each vehicle The label stores the unique identification number (VIN code) of the vehicle in the label. The vehicle label is packaged with plastic magnets, which is convenient for adsorption on the surface of the vehicle body.

Before the vehicle goes online, the staff will install the initialized label on the upper surface of the front hood of the car body.

The employees of the production line need to swipe their cards on the high-frequency card reader at the station to complete the on-job certification, and the system records the on-job status information of the employees at the current station.

Before the vehicle goes online, the staff scans the VIN barcode of the body, and the UHF reader writes the VIN code information into the vehicle RFID tag within the field strength range of its antenna. The subsequent stations complete the production line vehicle monitoring and monitoring by reading and writing the body RFID tag. data collection etc.

At the assembly station, after the UHF reader/writer reads the vehicle label, it prompts the parts installation information of the corresponding station. The staff installs the corresponding parts, and brushes the high-frequency RFID tags in the corresponding parts bins on the high-frequency reader. The system obtains the component installation information of the corresponding vehicle and the staff information for later quality tracking, the system returns the material consumption information to the LES system, and refreshes the information prompt of the component installation of the station until all the parts to be installed at the station are installed. In the link of supplying to the stations of the production line, after the production and logistics department delivers the parts to the stations, the system updates the quantity information of the parts.

At the off-line station, the UHF reader reads the vehicle tags, the system checks the assembly information, and the staff removes the RFID tags for recycling.

4. Automobile assembly manufacturing execution system based on RFID technology

4.1, system function modules

The functional modules of the automotive assembly manufacturing execution system based on RFID technology are mainly divided into four functional modules: workshop production management, production line visualization, RFID tag management, and workshop personnel management. The specific functional structure is shown in Figure 1:

Workshop personnel management: manage the basic information of workshop personnel, configure employee job information, and provide relevant basic data for functions such as personnel work records and vehicle parts data collection.

Assembly workshop production management: At the planning level, coarse-grained production plans are obtained from the ERP system, and decomposed into daily production plans to guide workshop production. Guide and monitor each assembly step of the vehicle during the vehicle production process to standardize the entire production process, including providing assembly work instructions to assembly workers, automating vehicle assembly and material consumption data collection, and providing accurate parts information , assembler information, supplier information assembly records, and feed back the consumption data of station materials to the MES system in real time.

Production line visualization: Provide real-time feedback on production line and vehicle status information, which is helpful for managers to grasp the production situation in real time.

RFID tag management: responsible for the issuance and management of personnel tags, issuing and recycling tags during the recycling of vehicle tags, and asset management for vehicle tags.

4.2, system architecture

This system uses the RFID software middleware deployed in the workshop server to manage the workshop reader network in a unified manner, which is conducive to shielding the differences of RFID equipment and improving the stability and efficiency of the RFID reader network, and the RFID equipment does not depend on the station Terminal, no special configuration is required for the station terminal, which is convenient for deployment. The structure of the automobile assembly manufacturing execution system based on RFID technology is shown in Figure 2:

4.3, system software architecture

This system adopts B/S architecture, and in the J2EE development environment, combined with mainstream open source frameworks such as Struts2, Hibernate, Spring, DWR, etc., it has good cross-platform compatibility. The software architecture of the automobile assembly management system based on RFID technology is shown in Figure 3:

The Struts framework is a framework based on the MVC (Model-View-Controller) pattern, which is mainly realized by JSP and Servlet technologies. The system uses the Struts framework to integrate Servlet, JSP, custom tags and information resources to complete the system’s response to the front page operations.

The system uses Hibernate as the Java persistence layer solution, establishes object/relational mapping, and realizes the conversion from relational data to object data.

As a web framework that implements Ajax interaction capabilities, DWR can expose any Java object on the server side as a remote object that can be accessed through JavaScript in the browser. This system uses the DWR framework to realize the forward and reverse Ajax functions, pushes the data acquired by the RFID processing module to the response business module in real time, reduces browser redundant requests, reduces server pressure, and improves system operating efficiency.

The Spring framework is a lightweight J2EE framework implemented on the basis of J2EE. This system uses it to provide Bean configuration, AOP support, abstract transaction support for the program, organize the business service layer and data access layer objects in the system, and realize the loose coupling between the creation and use of component objects.

5. Conclusion

According to the actual operation of the system on the assembly line of an automobile manufacturer in Anhui, the automobile assembly manufacturing execution system based on RFID technology enables the enterprise to timely and accurately grasp the status of the production line and improve production efficiency, which is indeed beneficial to the MES system and LES system. Work together to provide accurate data guarantee for product quality tracking.