Related schemes of RFID technology applied in mail processing

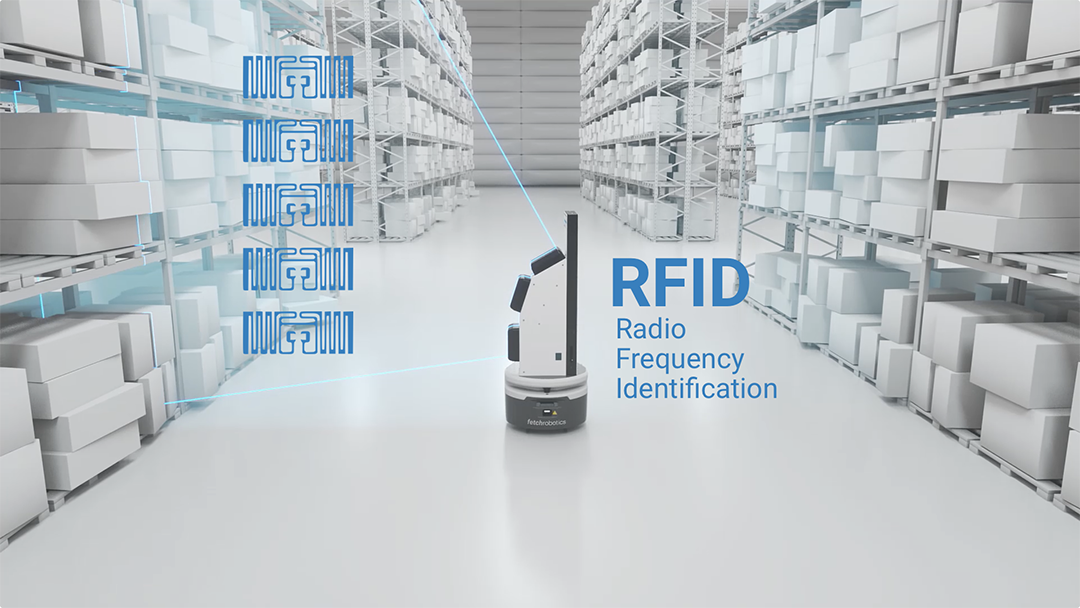

Radio frequency identification technology (RFID) has the advantages of non-contact, non-line-of-sight identification, rewritable information, greater reading and writing distance, large capacity (relative to barcodes), and multiple identifications. It has been used in logistics supply chain management, production management and Control and other fields have been widely used. In the logistics industry, express service giants UPS and DHL have launched RFID system testing and practice, and the International Postal Union has also tested the use of RFID technology for international mail to improve the efficiency and quality of mail delivery.

This paper discusses the application of this technology in mail processing, including the application schemes of parcels, hanging brushes, express packages and mail bags in different processing links in different occasions such as postal branch offices, mail processing centers and mail transfer stations.

Application system structure

The application system mainly involves an RFID data information collection system and an RFID data processing system. The system adopts the client/server structure, mainly considering that the RFID system needs to have a strong real-time response, and the client/server structure can well meet this requirement. Install the database software on the server to store all the data: install the application program on the PC, the application program runs on the PC, and perform database operations through the LAN.

System frequency band and label selection

The frequency of an RF system application is the primary factor affecting system performance. It is directly related to elements such as the recognition distance of the system, the degree of signal attenuation, and the reading and writing speed.

LF and HF systems are mainly used in occasions where the distance is relatively short and high penetrability to objects is required, such as animal identification or access control systems.

UHF and μWF systems have a long range of action, good performance in adapting to high-speed motion of objects, large data volume, and fast data reading and writing speeds. The typical distance is 1-15m. They are widely used in supply chain management, traffic and logistics management, luggage tracking and other fields. . Among them, the 915MHz system usually uses passive electronic tags, which are widely used in logistics systems, and have formed ISO series standards, and the technology is relatively mature. Microwave (μWF) systems consume a lot of power, and generally require active electronic tags.

From the point of view of the production requirements of general mail, it is generally required that the recognition distance should be up to 3m (during loading and unloading), so LF and HF systems are not suitable. If you use microwave, you need to use active electronic tags, and its recognition distance can meet the production requirements of general mail, and the recognition distance of active electronic tags will gradually shorten with the consumption of battery power, and the price of tags is high, so it is difficult to It is used by the postal general mail system. The UHF frequency band RFID system, its technical characteristics such as identification distance are suitable for the identification requirements of general postal production, and it is technically feasible.

To sum up, the frequency band of the mail or pouch RFID system involved in this article is the passive tag of the UHF (Ultra High Frequency) frequency band.

Technical requirements for readers

Readers can be divided into fixed-mounted readers and dedicated pocket tag writers according to different applications. Readers should be scalable, adaptable and capable of backward upgrades and compatibility.

Fixed readers are generally used to read RFID tag tags on moving objects. In the implementation scheme introduced in this article, it is used for platform handover, mail bag opening, bulk sorting and general package sorting. The data collected by the fixed reader is sent to the upper computer after filtering and deduplication, and then sent to the RFID data processing system.

The special bag tag writing device is mainly used for parcels, hanging brushes and express bag sealing links.

The special bag tag writer is mainly composed of small antenna, radio frequency reading and writing module, barcode reading module, embedded system module and related power supply and other components. When the mail bag is sealed and issued, the paper barcode bag tag and the radio frequency bag tag are manually put into the reading and writing area at the same time, and the bag tag writer collects the 30-digit barcode information of the paper bag tag by the barcode reading module, and completes the RF bag tag information At the same time, upload information to the RFID business information system in real time.