Overview of electronic label technology and its application in warehouse management

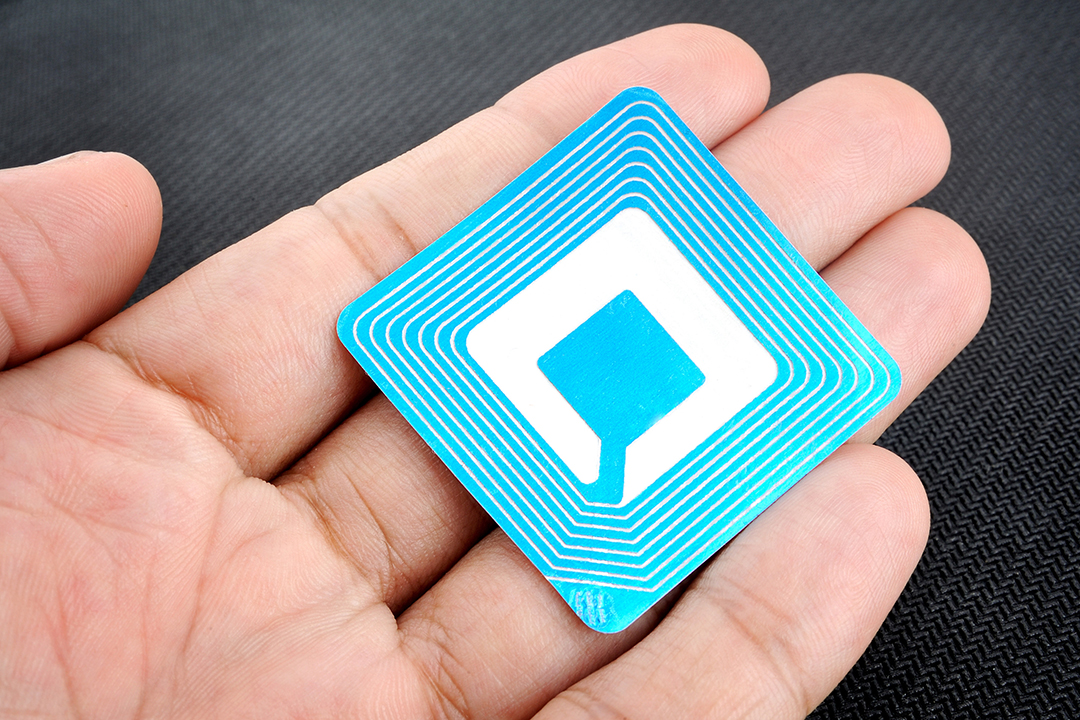

Radio frequency identification technology (RFID) is the abbreviation of Radio Frequency Identjfication, which is a non-contact identification technology and a more specific technical name for the application of radio technology in the field of automatic identification. Electronic tag is a popular name for Radio Frequency Identification (RFID).

It automatically identifies the target object and obtains relevant data through radio frequency signals. The identification work does not require manual intervention and can work in various harsh environments. This electronic tag has the advantages of waterproof, antimagnetic, high temperature resistance, long life, small size, long reading distance, encrypted data storage and batch reading, and can identify high-speed moving objects, etc. In recent years, RFID technology has been widely used in warehouse management. At present, the main application modes are warehouse management and logistics tracking management.

1. Basic structure and working principle of radio frequency identification technology

1.1, Basic structure of radio frequency identification system

The radio frequency identification system consists of two parts, namely electronic tags (transponders, Tags) and readers (reading heads, Reader). Electronic data information in agreed formats is usually stored in electronic tags. In practical applications, electronic tags are attached to Stored on the object to be identified (surface or interior). When the object to be identified with an electronic tag passes through its readable range, the reader automatically reads the agreed identification information in the electronic tag in a non-contact manner, thereby realizing automatic identification of items or automatic collection of item identification information It can further realize management functions such as collection, processing and remote transmission of object identification information through computers, PLCs and their networks.

1.2, the working principle of radio frequency identification technology

Between the electronic tag and the reader, the coupling element is used to realize the spatial (non-contact) coupling of the radio frequency signal. In the coupling channel, according to the timing relationship, the energy transmission and data exchange are realized.

The operation principle is as follows: the information to be sent by the reader is encoded and loaded on a carrier signal of a certain frequency and sent out through the antenna. This signal is modulated, decoded, and decrypted, and then judged on naming requests, passwords, permissions, etc. If it is a command to read information, the control logic circuit reads the relevant information from the memory, and sends it to the reader through the antenna in the card after encryption, encoding, and modulation, and the reader decodes, decodes, and decrypts the received signal Send it to the central information system for relevant data processing: if it is a command to modify the information, the relevant control logic will increase the working voltage of the internal charge pump to provide energy for rewriting the contents of the EEPRROM: if it is judged that the corresponding password and If the permissions do not match, an error message will be returned.

2. Types and characteristics of electronic tags

2.1, Types of electronic tags

The tags containing batteries are called “active electronic tags (ActiveTags)”, and the tags without batteries are called “passive electronic tags”: “active electronic tags” have high working frequency bands, long recognition distances, and read The communication rate between writers is also high. The “passive electronic tag” is the opposite.

2.2. Characteristics of electronic tags

(1) Miniaturized volume and diversified shapes

RFID is not limited by size and shape in reading, and it does not need to match the same size and printing quality of paper for reading accuracy. In addition, RFID tags can be miniaturized and developed in various forms, such as card-shaped, label-shaped, ring-shaped, button-shaped, pen-shaped, etc., with printed antennas sealed inside to apply to different products.

(2) Pollution resistance and durability

The carrier of traditional barcode is paper, which is easy to be polluted, but RFID has strong resistance to substances such as water, oil and chemicals. In addition, because the barcode is attached to the plastic bag or the outer packaging carton, it is particularly vulnerable to damage: the RFID tag stores the data in the chip to avoid contamination.

(3) Reusable

Today’s barcodes cannot be changed after they are printed, but RFID tags can repeatedly add, modify, and delete data stored in RFID tags to facilitate information updates.

(4) Penetrating and barrier-free reading

In the case of being covered, RFID can penetrate non-metallic or non-transparent materials such as paper, art materials and plastics, and can perform penetrating communication. The barcode scanner can only read the barcode when it is in close range and there is no object blocking it.

(5) Large memory capacity of data

The capacity of barcode is 50Bytes, the maximum capacity of 2D barcode can store 2 to 3000 characters, and the maximum capacity of RFID is several MegaBytes. With the development of memory carrier, the numerical control capacity also has the trend of expanding constantly. In the future, the amount of data required to be carried by items will increase, and the demand for expanded capacity of tags will also increase accordingly.

(6) Security

Since the electronic label conforms to the ISO 15693 standard, it has an internationally unified and non-repeating 64-bit unique identification internal code. This internal code is solidified in the chip by the manufacturer before leaving the factory and cannot be copied and changed, so it can uniquely identify objects. Attributes: Data transmission can adopt key authentication and multiple encryption methods to ensure system security.

(7) Quick Scan

Barcodes Only one barcode can be scanned at a time: RFID recognition reads several RFID tags.