Analysis on the application of RFID in food cold chain logistics

With the development of the economy and the improvement of living standards, people’s demand for fresh food has increased, and people have paid more attention to the quality and safety of food. The increase in demand has promoted the development of the cold chain logistics industry, and the requirements for quality and safety have promoted the development and application of new technologies. As an automatic identification and data acquisition technology, RFID technology can track the cold chain process and monitor temperature changes when it is integrated with a temperature sensor. The automatic acquisition of data simplifies the logistics operation process such as cold chain transportation and storage, shortens the logistics time, and reduces the logistics cost. Monitoring temperature changes and managing the logistics environment can ensure food quality, reduce the possibility of food spoilage, and improve food safety. RFID technology can track and record the whole process of logistics. Once a food safety problem occurs, it is convenient to trace the source and clarify responsibilities, thereby reducing economic disputes.

1. Introduction to RFID technology

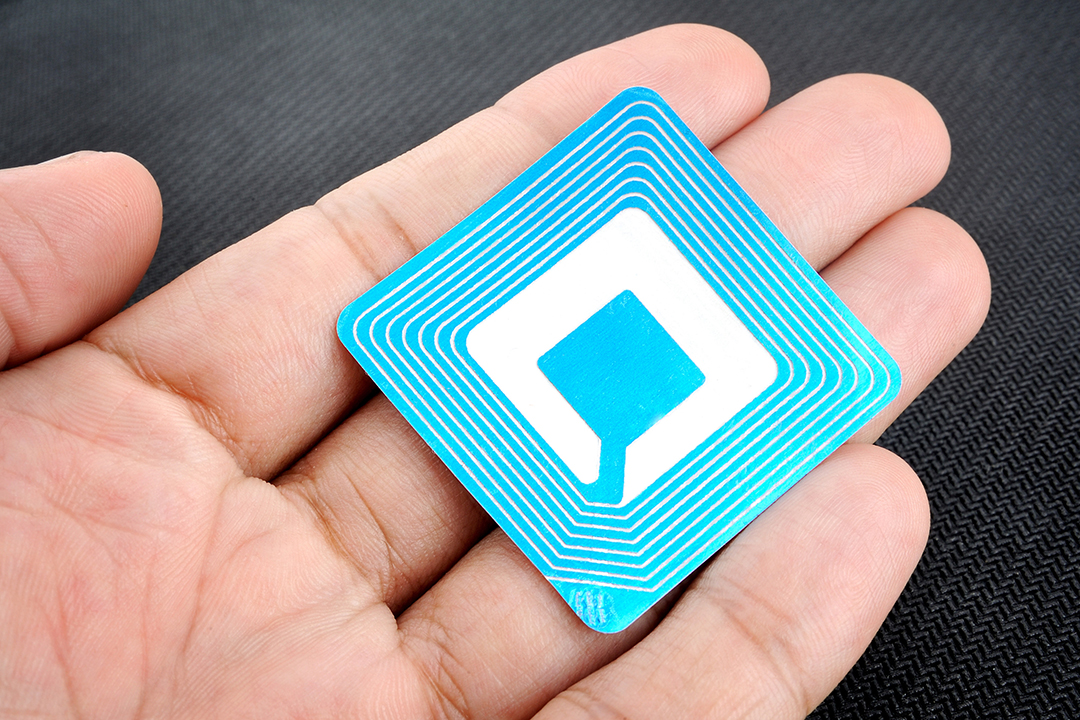

RFID (Radio Frequency Identification Technology) is a technology that automatically identifies the ID of a target through radio frequency signals to obtain object information and obtain related data. RFID technology can realize moving target and multi-target identification, can penetrate non-metallic materials, has large data storage capacity, strong anti-interference ability, strong environmental adaptability, and can be widely used in various occasions. The RFID system consists of three parts: electronic tags, readers and application software systems. The electronic tag has a unique identification code (ie ID), integrates a chip and a temperature sensor inside, stores product information and collected temperature data, and can actively transmit the stored information. After the electronic tag enters the magnetic field of the reader, the reader reads the tag information and sends it to the application software system for data processing.

Electronic tags come in a variety of forms, can be conveniently placed where needed, can be applied in liquid and metal environments, can be washed and withstand extreme temperatures, and can be combined with sensors that detect parameters including temperature, humidity, biology, and chemistry. Various new types of tags expand the scope of RFID applications.

2. The impact of RFID on each link of cold chain logistics

2.1. The production and processing links are convenient for retrospective tracing

Fresh food generally comes from planting and breeding bases. Production and processing plants need to set a label for each supplier or variety of food, enter initial information, and store basic information in the RFID label. Before the production and processing plant purchases the goods, the labels are handed over to the supplier in advance, and the labels are placed in the package when the goods are shipped. When the goods arrive, the factory collects information through the RFID reader, obtains the product information and temperature data in the chip, and transmits it to the back-end system. The system automatically generates a graph of temperature changes during the entire logistics process. If the temperature exceeds the preset temperature range, the factory can be rejected directly. The RFID system speeds up the inspection of incoming goods, reduces the error rate, and provides basic information for the computer system of the production and processing plant, and provides source data for product traceability. In addition, once the purchase process is over, the factory can know the exact delivery quantity of the supplier, which is convenient for settlement of the payment.

Processing enterprises have installed temperature and humidity monitoring systems in their workshops to monitor the environmental conditions of the food processing process. After the packaging process is over, an RFID label is pasted on each package, and the factory adds processing information to the RFID label, including processing technology, processing date, additives used, food weight and grade, shelf life and other information. At this time, the label already contains supplier information and processing information. Once a food safety accident occurs, it is convenient to trace afterwards; and the factory can know the quantity that can be supplied to the retailer, which is convenient for arranging shipment and scheduling staff, and improving work efficiency.

2.2. Improve efficiency in storage

The cold chain logistics warehouse is equipped with a reader. When the labeled food package enters the sensing area, the reader can dynamically identify multiple labels at one time from a distance and transmit the product information in the label to the warehouse management system. The warehousing management system compares the quantity, type and other information of the goods with the warehousing plan to confirm whether they are consistent; analyzes the temperature information in the label to judge whether the food logistics process is safe; and enters the receiving time and quantity into the back-end database. The warehousing system arranges the shelf position according to the warehouse information, calculates the moving distance of the goods into the warehouse, and tracks the goods to ensure that the goods are placed in the correct position. After the goods are put on the shelf, the tag periodically records the measured temperature according to the predetermined time interval, and transmits the temperature data to the reader in the warehouse, and finally summarizes it to the back-end database for centralized management and analysis. When leaving the warehouse, the reader also reads the label on the food package, and the storage system compares it with the export plan to record the time and quantity of leaving the warehouse.

In the whole warehouse management link, the application of RFID system can improve the operation efficiency of each link. The data entry and exit of the warehouse has been changed from manual to electronic data import, which reduces the manual entry process. When large quantities of goods enter and leave the warehouse, RFID can identify them in batches, which can significantly improve efficiency and save manpower. The basic information of the goods, including the place of origin, type, temperature, etc., can also be obtained from the label, which can be checked directly at the warehouse door, reducing the steps of checking and unpacking inspection, and saving operating time. The temperature information of the goods is collected at any time during the inventory process, and the system can issue an alarm when an abnormality occurs, reducing the rate of cargo damage. If RFID technology and EDI technology are combined, it can increase the amount of cross-dock operations, greatly shorten the time of food logistics, reduce inventory levels, and thereby reduce logistics costs.

2.3, real-time tracking of transportation links

In the process of cold chain transportation, the transportation vehicles are equipped with fixed labels, and the packaging of cold and fresh food is also equipped with labels, and the actual temperature is detected and recorded according to the established time interval. There are two ways to read tag data. One is to install a fixed RFID receiving and forwarding device at some key points of the transportation line, such as warehouses, stations, docks, bridges, gateposts, etc. When the vehicle passes by, the fixed device Reading; the other is to install a reader on the vehicle to read the tag data at a predetermined time interval, all of which need to use GPS technology to automatically upload the tag information and location information to the back-end information platform. During transportation, once the temperature is abnormal, the system will automatically alarm, and the driver can take measures at the first time, thus avoiding the risk of chain disconnection caused by human negligence. The joint application of RFID and GPS technology can realize geographic location tracking, real-time temperature monitoring and cargo information query, accurately predict the arrival time of vehicles, optimize the cargo transportation process, reduce transportation time and loading idle time, and fully guarantee the quality of food.

2.4. Reduce management costs in the sales process

Using RFID technology, the seller can obtain accurate delivery information and prepare for the purchase in time. After the goods arrive, use the reader to collect the label information, compare it with the purchase plan, and judge whether it is consistent; analyze the temperature change information of the goods, judge the quality of the food, and decide whether to accept the goods, making the inspection work more efficient. Install supporting facilities in retail stores or supermarkets to monitor food labels in real time to ensure that the temperature is within a certain range to maintain the freshness of food. RFID tags can monitor the expiration date of some time-sensitive commodities, such as tracking a certain food, once the expiration date is exceeded, the tag will send an alarm to reduce the rate of damage to the goods.

2.5. Consumer satisfaction improvement

There are RFID tags on the outer packaging of cold and fresh food. When customers push the shopping cart through the aisle equipped with RFID readers, the reader can identify the type, quantity, amount and other information of the goods in the shopping cart at one time. Displaying the total consumption amount of the customer, the cashier does not have to scan the products one by one, reducing the time for consumers to queue up for checkout, and making the shopping process more convenient. Inquiry facilities are installed in retail locations to allow consumers to inquire about food information by themselves, understand the process of food from origin to sales, make supply chain information transparent and detailed, and improve consumer satisfaction with retail companies.

The application of RFID system by retailers can create a safe consumption environment for consumers, establish a good corporate image, help stabilize and expand consumer groups, and enhance market competitiveness.

3. Conclusion

With the application of RFID technology, the entire flow process of fresh food from the beginning of production will be tracked in a timely and accurate manner, which simplifies the operation process of the enterprise, shortens the operation time, and meets the requirements of cold and fresh food. At the same time, it shortens the time of purchase and delivery, improves the efficiency of loading and unloading, improves the accuracy of each link of logistics, shortens the supply cycle, optimizes inventory, and reduces the cost of cold chain logistics. After the temperature sensor is integrated with the electronic label, the enterprise can monitor the temperature throughout the process, promote the coherence of the cold chain logistics process, prevent chain breaks, ensure the traceability of food quality, and improve food safety. The joint application of RFID technology and logistics technologies such as GPS, GIS, EDI, and WMS can comprehensively improve the management level of food cold chain logistics and bring about fundamental changes in the cold and fresh food industry.

RFID technology has broad application prospects, but there is a lack of national standards and only some industry standards. There are differences in the frequency, coding and data content used by enterprises. It is difficult for readers and tags to be fully universal, and data exchange and coordination between enterprises are limited. In addition, the value of cold and fresh food is low, and the price of RFID tags is relatively high. With the development of the economy and the advancement of technology, these problems will be solved, and RFID technology will be widely used in other fields.