Analysis and Design of Inventory Management System Based on RFID Technology

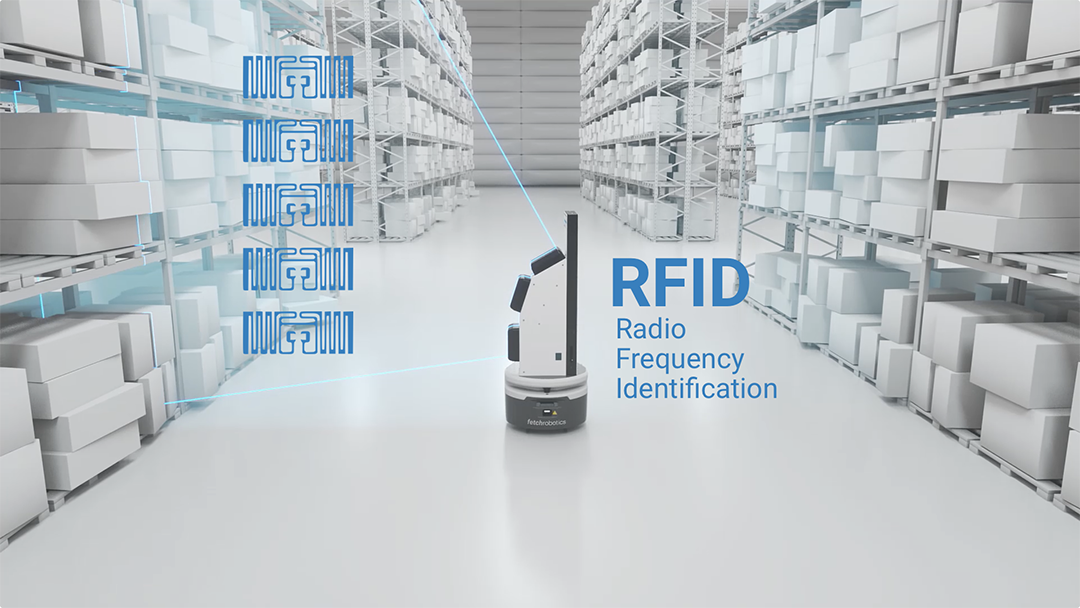

Inventory management systems now rely on passive RFID technology for real-time automatic identification of products. For many applications, the return on investment for using RFID is acceptable. These systems must be able to capture the information of all products in stock in real time, which requires that the RFID system must be able to read 100% of all tagged items. The readability of an RFID system is a function of many variables including: tag size, orientation, placement, and interrogator antenna (IA) design. Unfortunately, for all single-antenna designs there is a “black hole” of unreadable tags. By analyzing and identifying these black holes, the industry has developed a method to achieve 100 percent readability using the multiplicity of the ISO 15693/ISO 18000-3 (13.56-MHz) item-level system.

High frequency (HF) RFID systems such as smart trucks/containers play a role in this area, and many manufacturers and solution providers offer such products. These inexpensive systems employ passive RFID tags (less than 25 cents each in mass production), a technology that holds great potential for tracking clinically high-value items, some of which have a limited shelf life. For example, more than 250 stents, worth an estimated $375,000 in total, may be stored in lockers typically found in a hospital’s cardiac catheterization laboratory. Depending on the size of the hospital, there may be four such lockers in use, the contents of which are consumed every 4 months, which equates to a value of up to $1.125 million in items “handled” per year by one such locker. Implantable cardiac defibrillators (ICDs) are also high-value items in hospitals. They are small (approximately 3 & TImes; 4 & TImes; in packages) but cost $10,000 to $20,000. They are usually stored in a secure space such as a locked locker. In such applications, the use of RFID can reduce the cost loss caused by under-stocking or over-stocking of certain items, and can better control the whereabouts of these valuable items.

A basic RFID system consists of a host system and multiple RF components (Figure 1). RF components include a radio frequency interrogator (reader and antenna) and tags. The purpose of the interrogator is to communicate with the field tag, and for passive systems, the interrogator also provides power to the tag through the transmitted RF signal. The interrogator is responsible for protocol processing, powering the tag, reading tag information, writing information to the tag, and ensuring efficient delivery of information to the host system.

The ISO 15693 standard stipulates that passive tags are only activated when they are “in” a radio frequency field. To activate a passive tag, the voltage (VTag) induced by the RF field must be high enough to reach the minimum voltage level required for the RFID chip embedded in the tag to operate. The VTag value is a function of the tag size/direction and the magnitude of the magnetic field strength. For an ideal loop, VTag can be expressed as:

VTag = 2πf0NQB(Scosa) (1)

in:

N=Number of windings of the label coil,

Q = quality factor of the label,

B=magnetic field strength,

S = area of label coil,

a = orientation angle of the label

Based on RFID inventory management diversity system design

Figure 1: A basic RFID system consists of a host system and multiple RF components

The magnetic field strength (B) is generated by the circular interrogator antenna (IA), which can be expressed by Equation 2:

B = (μ0INa2)/2r3 (2)

in:

I = IA coil current,

N = number of IA coil windings,

a = IA coil radius,

μ0 = permeability of unobstructed space,

r = distance to IA.

From these equations, we can deduce the relationship between tag size and orientation, and the field strength induced along the IA axis. When the tag and the interrogator are close, although the coupling relationship can be established with the help of the complex reactive near-field relationship between the two, it can only be barely expressed by the above equation, especially when r << a and deviates from the axis of the interrogator , its coupling relationship is difficult to predict accurately. In real object-level applications, the tags are usually close to the interrogator antenna, so for this reason, the selection does not depend entirely on these predictions.

Based on RFID inventory management diversity system design

Figure 2: The smallest RFID tag used in this study, the size of a coin

This mechanism, which is critical to understanding RF black holes, is both relevant to the design of the IA and the tag, and is influenced by the interaction between the two. HF tags come in a variety of designs and sizes, generally falling into two broad categories: flat and three-dimensional (3D) designs. Flat labels are the more common thin paper carrier type, while 3D labels contain ferrite and are much smaller. The labels used in this study were all flat. Since performance is a function of both the tag and the IA, the capabilities of three commonly used tags of different sizes are explored here, with the smallest tag shown in Figure 2 and two IAs of different sizes and distinct designs shown in Figure 3. For the case of only one tag and multiple tags in the sensing field, the response of the reader is recorded. This is typical for practical applications where many products are often placed next to each other in the induction field. The purpose of these measurements is to attempt to delineate a three-dimensional space representative of the actual system and to locate any existing RF black holes.

Based on RFID inventory management diversity system design

Figure 3: Two typical RFID interrogator antennas (IA), with some critical locations in the PCB traces for both antennas

The position information of the RF black hole can be used to locate the position of other antennas, allowing them to function in a “black hole-free” diversity system. A commonly used diversity system (Figure 4) incorporates single-pole, multiple-throw switches to route multiple antennas to the RFID interrogator. Such systems are designed to frequently switch among numerous antennas, using PIN diode switches that have a significantly longer mean time between failures (MTBF) than the mechanical relays used in RFID systems with only a single movable antenna. At present, commercial diversity RFID systems integrating readers with multiplexing circuits (some can handle up to 256 interrogator antennas) have been launched on the market, and the price is relatively acceptable.

Based on RFID inventory management diversity system design

Figure 4: This block diagram shows a diversity system using multiple CAT5 cables for RF and digital control signals

In the entire test setup, the RFID reader is considered the most critical part, and it is specified to work in accordance with the requirements of the ISO 15693/ISO 18000-3 Mode 1 protocol. The ISO standard is mature and globally recognized, with a wide range of reader models and tag sizes available from a number of established manufacturers. Due to the large number of items that may be found in one scan, the selected RFID interrogator has the capability to read a minimum of 100 tags per scan. The (radio frequency) output of the reader chosen for the test system was 1W, from a reliable manufacturer. Low-power (200 to 250mW) readers were also evaluated in this test, but the read range was found to be less than ideal for certain object-level applications. Readers up to 10W were also evaluated, but no significant improvement in performance was found. Additionally, the high power levels combined with the recommended IA exceed regulatory radiation levels. And the cost of these high-power readers is nearly an order of magnitude higher than the low-power version used in the actual test.

Because of the large number of tags placed very close together in a real-world usage model, designers are concerned that interrogator detuning effects will degrade interrogator performance and thus prevent proper tag reading. The measured return loss response (S11) of a single interrogator antenna is close to 50 (Figure 5), which matches the characteristic impedance given by the reader. Figure 5 also shows the S11 response of the interrogator under different tag size conditions. Larger tags, which couple very well to the interrogator, have a significant impact on the S11 response, placing it outside the stated requirements of the interrogator. Some interrogators cannot read tags that are too close together at all, and the manufacturers say that the height mismatch will “swallow” the receiver circuitry so that the tags cannot be detected. But the readers used in this study performed well under such conditions. The single-tag (vs. multiple tags) degradation for the interrogator S11 is not severe except for placing the tag very close to the interrogator’s PCB trace. It is hoped that the RF black holes uncovered by single-tag testing will be similar to those found in multi-tag testing to speed up the verification process of future interrogator designs.

A simple passive RF probe can be useful for pretesting (Figure 6). The probe contained a tag whose RFID chip was replaced by a light-emitting diode (LED), which can be used to indicate the presence of an EM field; three probes were assembled using tags of different sizes. While crude for a dollar, this test kit is effective as a real-time probe that can locate RF black holes. The probe was able to locate radio-frequency black holes that were not evident at the time by intuition. When the tag is very close to the interrogator, the RF black holes are exposed and distributed symmetrically around the ring PCB trace. This is verified by the interrogator’s S11 response, where no changes were observed when the tags were placed in these locations, and this is also evidenced by the S21 measurements recorded from the small ring probe.

This demonstrates that an RF black hole can be observed with a vector network analyzer (VNA) by observing the response of S11 and S21 as the label or PCB wire loop moves. Further inspection of tags of different sizes and the interrogator antenna revealed the presence of a black hole at the same location on the PCB trace. The test found that the area where the reading effect is not good is quite large, and they are all near the PCB wire loop, where the label is likely to be placed.

Based on RFID inventory management diversity system design

Figure 5: Return Loss Response (S11) of a Single Interrogator Antenna Approaching 50

Based on RFID inventory management diversity system design

Figure 6: This RFID tag is used as a simple test probe with its RFID chip replaced by a light emitting diode (LED)

The RFID tag test bench was prepared with a variety of tag designs and orientation configurations (Figure 7). The configuration of the test bench includes up to 77 tags and is oriented in the x-y plane (parallel to the interrogator plane) as well as orthogonal to the interrogator plane. Each chip inside each RFID tag contains a unique identifier that can be read as part of the reading process; it marks the location of its test station. Interrogator response (ability to read the tag) is recorded in fixed increments above IA (Z-axis). In addition, the results of moving the card in the x-y plane of the interrogator in small step increments are recorded. Motion in the x-y plane is important as it allows for symmetrical alignment of the tag and interrogator wires and indicates RF black holes encountered during previous pretests.

Based on RFID inventory management diversity system design

It was found that the single- and multi-label test results agreed fairly well for both parallel and perpendicular planes. The results of the vertical plane measurements are consistent with a situation where high label-to-label coupling is the dominant trend, with deterioration when label spacing is less than 0.4 inches. The multi-tag test under the condition of vertical plane is to read more tags continuously; because of the high coupling between tags, the tags located in the radio frequency black hole can be activated, so it can be considered as the result of an activated tag, and Not directly from the querier.

Testing with tags pointing to the same plane as the IA indicated a black hole location common to all tag sizes and interrogator designs. As previously observed, RF black holes appear near the IA PCB traces when there is symmetry with the label. Figure 8(a) details the mapped response, clearly showing the RF black hole when the card is moved to the left or right so that the entire column of tags is symmetrical to the interrogator antenna wire. As the height increases, the label at the edge gradually falls out of the readable range. At this time, a pyramid can be used to describe the shape of the overall three-dimensional readable area. We also found that the size of the read region is proportional to the size of the interrogator and tags.

When the tag points to be orthogonal to the interrogator, the tag reading performance is considered to be poor because the tag and interrogator fields are orthogonal and not well coupled. The tag mapping for this orientation is shown in Figure 8(b). Tag reading works well when the tag is close to and parallel to the interrogator PCB traces, but not everywhere else. In the vicinity of the interrogator PCB traces, no RF black holes were found, which is different from the measured results of the symmetrical arrangement of parallel planes. Read performance is a function of height, especially for small tags, where performance deteriorates significantly with increasing height (relative to planar parallel responses); these results demonstrate that only larger ISO tags can be used in this orientation. Although the overall read performance in this direction is poor, the multi-antenna design of the diversity system improves the read performance.

Based on RFID inventory management diversity system design

As the test shows, none of the planar interrogator antennas can achieve a 100% read rate in its entire plane, and there is a large radio frequency black hole near the interrogator. Test results show that one hundred percent reads can be expected if multiple IAs are properly arranged. Tests have also shown that a properly designed diversity system can meet 100 percent read performance requirements across the entire surface, with no limitation on the number of objects. These results apply only to a sample of possible different label/querier combinations, some of which may satisfy the expected performance.

At the same time, we also investigated the dual-loop IA design. Clearly, for small tags, there is a prevalent RF black hole at the center of large single-loop IA designs. Modeling results for the dual-loop IA design showed a significant improvement in tag reading in the center region for the dual-loop design compared to a single-loop design of the same size. While a dual loop IA is not yet on the market, we built one and tested it. The results showed a significant improvement in reading for tags placed in the central region, but also suffered from symmetry effects at this location.

These test results were then applied to the design of a diversity system with the goal of achieving 100 percent read rates for inventory management applications. Another goal was to provide a flat design without major modifications to the existing hardware (shelves, cabinets, etc.), which would not reduce product space and be aesthetically pleasing. The design must also take into account any factors that may degrade performance, such as packaging. We have done extensive testing of stand and conduit products packaged in cardboard and sealed in foil-lined pouches, as well as marking and reading books in libraries for smart bookshelf applications. At the same time, ICD testing is also underway. It was found that relatively large packages presented the least problems, allowing the use of large ISO tags in parallel orientation with the RFID interrogator.

For object-level applications targeting racks, tagging them is considered appropriate because the tags can be placed as close to the interrogator as practically possible. For stand-off products, the label is placed on the bottom edge as shown in Figure 9(a); 100% readability is achieved even when packaged with a foil liner. Tests on larger ISO tags placed in an orthogonal orientation found that 100 percent reads were only achievable after the foil wrap was removed. Test results on ISO tags pointing vertically, wrapped in aluminum foil, were not good because the tag was sandwiched between metals, misaligning the tag and also reducing the RF field strength reaching the tag.

Design based on RFID inventory management diversity system

For book applications, ISO-sized labels are placed on the lower inside of the front cover (Fig. 9(b)). Even if the tag is at right angles to the reader, 100% reads can be achieved with large tags as long as the book is wider than 0.2 inches. When the width of the book is too small, the labels within each book are placed close together, effectively imparting a detuning effect on the labels, making reading difficult. It should be noted that 100% read rates will never be achieved for randomly placed tags no matter how hard one tries, and this study only focused on properly placed tags.

Early in the development of the interrogator design, it was understood that all combinations of single-loop antenna designs could be problematic because they were strongly coupled to each other, so that the measured performance of each single-loop antenna was therefore no longer valid . As a result of multiple modeling tests of various loop combinations, it was found that single and dual loop (often referred to as “digital eight”) combined architectures complement each other’s coverage, as demonstrated in early testing. Additionally, the coupling between the concentric rings/”digital 8″ was predicted to be low, and later testing proved to be better than -20dB.

The resulting queryer design is shown in Figure 10. The design takes into consideration the actual storage situation of the stand and ICD, as well as the situation of books or any other products of similar size and composition. The original design included three loop/digital 8 pairs. This configuration is designed for the intended application (stand/ICD/book) to read any tag in the same plane as the reader, or any tag that is perpendicular or parallel to the side wall of the reader. Two digits of 8 were added later to evaluate additional tag orientations (perpendicular and parallel to the back wall), which gave it the ability to read arbitrarily oriented tags with a single planar reader configuration. The principle of designing interrogator antenna layout and spacing is to achieve the best performance with the fewest antennas. As shown in Figure 10, this layout allows multiple traces to complete the trace length of the PCB. These long, closely spaced segments facilitate tag reading across the entire surface.

Based on RFID inventory management diversity system design

Adjustments are made to each interrogator antenna within the design for impedance matching favorable to the tag field conditions. The impedance requirements of the reader/writer stipulate that the IA should meet the system characteristic impedance of 50-?. In order to adjust the tag’s response in the presence of the tag, the performance when the tag is not present will no longer be optimized. A compromise was made between these two cases so that in the presence of any number of tags the match is equivalent to a VSWR of less than 2.0:1. Previous research has tested the relationship between the performance of readers and VSWR, and the situation shows that: unless the matching VSWR is significantly higher than 5.0:1, otherwise the performance does not deteriorate significantly. It is worth mentioning that, from Equations 1 and 2, it can be seen that in order to double the read range, the current in the IA generated by the reader must increase by the order of the cubic. Since the power is proportional to the square of the current, the power of the reader must be 64 times higher to double the reading distance in this RFID system (where P is proportional to r6); a reasonable VSWR response in the system will not cause induced voltage significant loss.

Record the test results with the aid of a commercial reader/multiplexer and test setup, as shown in Figure 11. The mapped responses for all 8 antennas are shown in Figure 12. Mapping responses clearly show that 100 percent read rates are available for many tag orientations. Also, it was found that there was a huge amount of antenna “redundancy” where tags were read by more than one antenna, so it was possible to reduce the number of antennas participating in the scan to three and still achieve 100% read performance. The interrogator/multiplexer also has a multiplexing function that can handle up to 256 interrogator antennas. Using the common CAT5 cable described by the reader/multiplexer manufacturer, the smart truck can be easily configured and assembled to accommodate up to 16 RFID containers, each of which can switch between 16 antennas. With the use of a balun, RF energy is carried over one of four pairs of CAT5 twisted-pair cable (100-), with the remaining six wires used as digital input/output (I/O). At 13.56MHz, CAT5 cable has relatively low loss, allowing 100 percent read performance over 100 feet of cable.

Based on RFID inventory management diversity system design

Several issues encountered in this study can be considered as limitations for some applications, such as capture speed. With the integrated multiplexing technology, switching can be performed sequentially; the time required for the reader to capture tags is directly proportional to the number of tags in the field. The time required to read the 77-tag testbed with all 8 interrogators was 40 seconds. After studying these datasets, it was confirmed that 5 of the queriers were completely redundant, and removing them reduced the overall scan time to 20 seconds. In the test field, we encountered no more than 50 products/shelf, usually 25, for rack applications, and the time it took to read them was under 15 seconds. The reader rate is a function of the transponder protocol (specified tag/second rate), the anti-collision algorithm, and the reader capability (throughput of delivering data to the host). The good news is that the progress of the new HF Gen2 RFID standard protocol is significantly accelerated, and corresponding readers/tags should be available in the market soon. In this application, time considerations are not an important issue, as inventory updates only need to be done at shift changes, 3 times a day. Some applications require both product tracking with RFID and identification of people via biometrics (fingerprints) or ID cards. They occur in busy areas where the reading interval between trucks/containers will be short, and scanning time is a factor. important parameters.

Design based on RFID inventory management diversity system

Another potential problem is related to narrow products, such as racks; there is a phenomenon that these narrow products have the potential to “tumble” when the shelf is not full. In this case, the tag is at right angles to the reader and may be at an unreadable height, especially if the product uses small tags. To circumvent this, moveable plastic grids/bookends are placed inside the shelves to prevent product from “falling over”

With the availability of inexpensive COTS hardware, merchants can configure cost-effective diversity systems that meet the specifications required by many inventory management applications. These systems are inherently modular and configured for integration into existing systems without significantly sacrificing product space or aesthetically. Item-level RFID technology incorporating multiplexing offers an acceptable solution for many applications, and is particularly attractive for tracking expensive clinical products such as stents and ICDs.